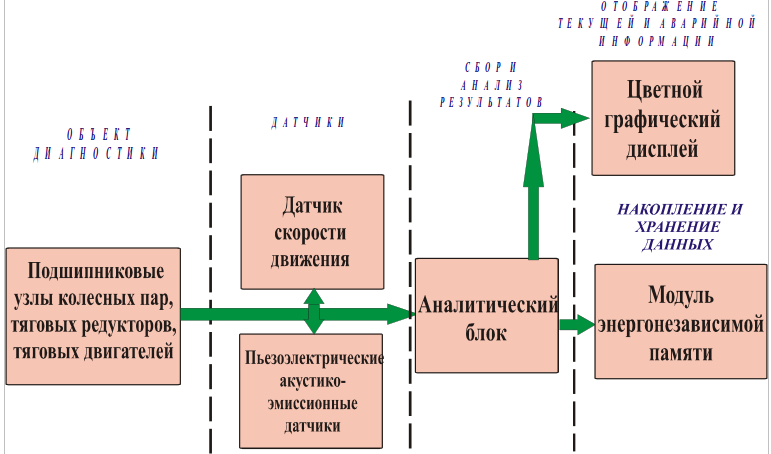

On-board acoustic emission diagnostics system of bearing units is intended for the constant control monitoring of axle boxes and operating generator bearing units condition; it allows to:

Developer: OOO METKATOM

System blocks delivery, personnel training, technology of diagnosis.

System delivery and installation is performed within three months.

The cost of on-board 12-channel system (for a passenger carriage with an undercar electricity generator) with account of installation and personnel training is included in the contract.

System cost in case of equipping carriage pilot batch is specified at the contract conclusion.

| PRESENT CARRIAGE PREVENTIVE MAINTENANCE SYSTEM | ON-BOARD DIAGNOSTICS SYSTEM ADOPTION FOR PASSENGER CARRIAGES |

| Periodic preventive maintenance and repair work costs with present maintenance system TO-3→TR→DR→KR are ≈ 600,000 roubles per carriage a year, out of which 10-15 % (≈ 90,000 roubles) are wheelpairs and undercar gears maintenance costs. | On-board diagnostics system allows to reduce unreasonable expenses, thereby units maintenance estimated expenditures according to their actual condition will be ≈ 20-25 % (≈ 20,000 roubles). Hereby annual saving rate will be SR= 90-20 = 70,000 roubles per equipped carriage. |

| Lubricant costs with the present lubricating system (at the cost of 1 kg of BUKSOL lubricant 50 roubles) are ≈ 30,000 roubles per carriage a year. | Bearing units lubrication according to their actual need allows to reduce unreasonable operations of lubricant final squeezing and reduce lubricant consumption by 45-50 % ( ≈ 15,000 roubles per carriage a year). Hereby annual saving rate will be SR = 30-15 = 15,000 roubles per equipped carriage. |

| Preventive maintenance costs according to structure TO-3→TR→DR→KR with the existing norms of overhaul life are ≈ 945,000 roubles per carriage a year. | On-board diagnostics system of bearing units adoption allows to increase overhaul life by 20-25 % of the existing norms (≈ 750,000 roubles per carriage a year). Hereby annual saving rate will be SR = 945-700 = 245,000 roubles per equipped carriage. |

TOTAL ANNUAL SAVING RATE |

|

| Per equipped carriage | SR= 70+15+245=331,000 roubles |

| Per wagon depot (with the average rolling stock of 300 carriage units) | SR=331 х 300=99,300,000 roubles |

OOO METKATOM technical director: V.S. Potapenko

Candidate of Science {Engineering}: D.V. Fedorov